PCB One-Stop Service

To ensure the correct assembly process, we initiate communication with the client before starting the design phase. We carefully analyze the documents we receive to ensure that all necessary documentation is complete. Once the client provides the gerber files, PLAB assists in setting up the BOM, searches for suppliers, purchases components, and carries out sample or mass production. If any difficulties arise, we actively engage in discussions with the client to produce customized products that meet their needs.

One-Stop Service

PCB Layout: Our professional engineers excel in PCB layout design, offering excellent product quality and competitive alternative plans.

PCB Fabrication: Upon receiving the gerber files, we adhere to manufacturing standards, and our engineers verify the files. Production begins in our plant, and once finished-product inspections are completed, the products are delivered.

Procurement: We have extensive experience in procuring components, allowing us to control the quality and cost of components. Additionally, we have established strong relationships with global suppliers to address any supply chain issues.

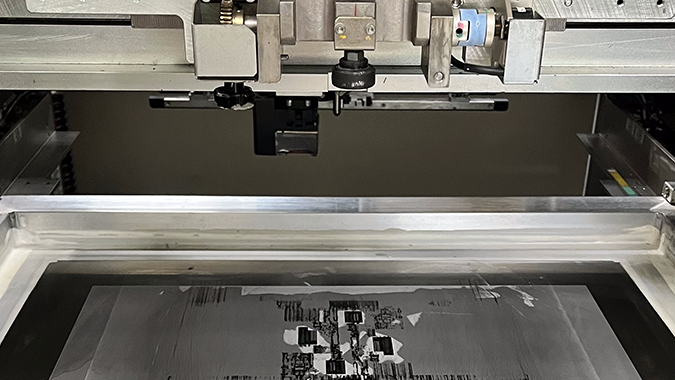

PCB Assembly: We provide advanced lead-free PCB assembly manufacturing that complies with RoHS standards. Our skilled workers use top-notch equipment for SMT and THT processes.

PCB Rework / Repair Service: We assist engineers in rectifying design issues, quickly modifying samples, and addressing any post-mass production corrections. Our goal is to help our clients reduce costs, making us a reliable partner